M7® Application Guidelines

The Balboa M7 control is a patented technology used in all of Balboa’s

current spa control systems.

It is a field proven control system that

provides additional reliability and ease of installation when compared

to older spa control systems. The software-based M7 control system makes

decisions based upon temperature

and flow conditions that exist within

the heater.

The system operates properly if there is a

minimum of 20 gpm flowing through the heater under all

hydraulic variables and at worst case conditions.

The goal for the spa

designer is to design a circulation system that, when used with the

proper pump,

will provide a uniform flow in either direction through the

heater.

This uniform flow must occur during heating and filtering cycles and must not fall below 20 GPM under any circumstances.

These

guidelines are intended to help you design your spa to achieve this

goal so that you can

take advantage of the Balboa M7 control system.

Please read these guidelines carefully and study

the plumbing schematics

before attempting to test the system or install it in a spa.

Balboa

strongly recommends your plumbing design be tested and proven with

calibrated water flow test meters,

to insure the minimum flow

requirements are achieved

Downloads:

M7 Sell Sheet

Basic Configurations Supported

Non-circ System

• A System that uses a 2-speed pump to heat and filter the spa plumbed on either:

1. Vacuum side heater - A heater that is located on the suction side of the pump

2. Pressure side heater - A heater that is located on the discharge side of the pump

• The heater requires at least 20 Gallons per Minute (GPM) of flow for proper function.

Circ System

• System that uses a dedicated 1-speed pump to heat and filter the spa plumbed on either:

1. Vacuum side heater - A heater that is located on the suction side of the pum

2. Pressure side heater - A heater that is located on the discharge side of the pump

• The circ pump motor must not exceed 2 amps

1. NOTE: The amperage limitation for the Circ Pump must be adhered to

so as not to overload the printed circuit board ampacity.

• The heater requires at least 20 Gallons per Minute (GPM) of flow for proper function.

System Mounting

Locating and mounting the system is very important when designing the equipment area and plumbing.

The

M7 technology opens up new possibilities since the system and heater

can be mounted on either the suction or pressure (discharge) side of the

pump.

To improve reliability, take steps to minimize vibration

from the pump(s) that could be transmitted to the system box. Using

rubber isolation pads under the pumps and flexible PVC between the

filtration pump and the heater are just two ways to help minimize

vibration.

Mount the system with the heater horizontal and as low as possible in the equipment compartment. Systems

mounted higher than the equipment floor risk air entrapment within the

heater tube, this can cause element damage, leading to a shorter useful

life.

Do not mount the system directly under the control

panel mounting location to avoid any potential for water to dip directly

on the system. Allow a drip-loop in the control panel wires to keep any

water that may travel down the wire from wicking into the system box.

Pressure-Side System Mounting

When

mounting the system on the pressure side of the pump, care must be

taken to mount the system in such a way that it is supported without

hanging on the plumbing. Each box has available ears that mount to the

back of the box with screws to facilitate this type of installation.

Suction-Side System Mounting

When

mounting the system on the suction (vacuum) side of the pump, care must

be taken to mount the system in such a way that it is aligned with the

suction port on the pump wet-end. The suction-side mounting can

generally be done much lower in the system, making it easier to keep

proper water flow in the heater at all times. The system should be

mounted with appropriate fasteners, using the feet molded on the bottom

of the box.

Note: When employing suction-side mounting, the

system may need to be placed on a spacer block so that it complies with

UL height requirements for electrically live components, in the same

manner as a pump motor. In the case of the system box, the live parts

closest to the ground will usually be the heater connections.

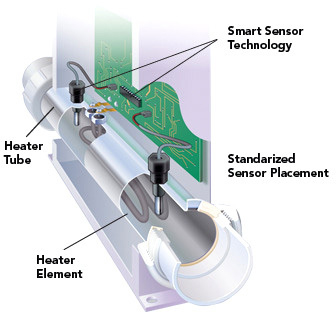

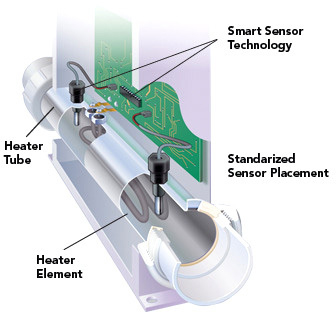

DID YOU KNOW...

…M7® systems offer a longer life expectancy than traditional, non-M7 technology?

Balboa’s systems feature automated diagnostics, electronic non-pressure switches, and dip switches, some of which can be configured in the field for greater flexibility.

These smart sensors offer multiple high-limit safety systems, eliminate excessive cycling and automatically adapt to flow direction.

To suppress this noise, Balboa’s line of controls features built-in hardware and software filters that optimize hot tub electrical operations.

Connectors that are mounted on the board are less susceptible to corrosion and are less likely to come loose since they are inside the enclosure. This also means that there are fewer holes in the enclosure so the entire system is protected against moisture and chemical intrusion.

Balboa’s EL/GL line of controls uses “zero crossing technology,” so those components are turned on and off at the optimal zero crossing of AC power. This means relays can be expected to last virtually a lifetime.

Balboa’s patented Piezo switch technology makes our panels more reliable due to its design with no moving parts, no contacts, no air gaps and no electrical current to cause problems.

Not only is the Piezo moisture proof, but the panel can be installed facing the inside of the tub for ease-of-use by the tub owner. The Piezo is also four times larger than the average membrane switch, which makes it the perfect size for a fingertip.

Equipment failure and servicing costs can be staggering over the life of a product. That’s why Balboa builds the highest reliability products available and even provides remote diagnostic tools to help OEM manufacturers and service technicians cut costs in the installation and repair processes.